310S stainless steel is a heat-resistant alloy famous for its outstanding high-temperature strength and oxidation resistance. You*ll often find it in extreme industrial settings like heat treatment furnaces or chemical processing plants. When heating 310S stainless steel〞especially at high temps〞induction heating is a go-to method. It*s precise, super efficient, and doesn*t even need physical contact to deliver heat effectively. Let*s break down what makes 310S special, how it behaves under high-temperature induction heating, and why this heating method rocks for these applications.

What is 310S stainless steel?

Simply put, it is the "low-carbon version" of 310 stainless steel, with a high chromium content (24-26%) and decent nickel content (19-22%).

These ingredients make it like a high-temperature warrior - able to resist oxidation, carburizing, and sulfurization in an environment of 1100-1150 ∼ C.

That is to say, this material is designed specifically for high-temperature heating

The superpower of 310S stainless steel:

1. Even at 1150 ∼ C, it's not afraid of rusting (imagine the toaster can still be used for ten years at maximum)

2. No deformation or collapse under high temperature (like heat-resistant Lego bricks)

3. Specially corrosion-resistant, especially in unfriendly chemical environments

4. Low carbon formula, not prone to "stone formation" (intergranular corrosion) like other stainless steels

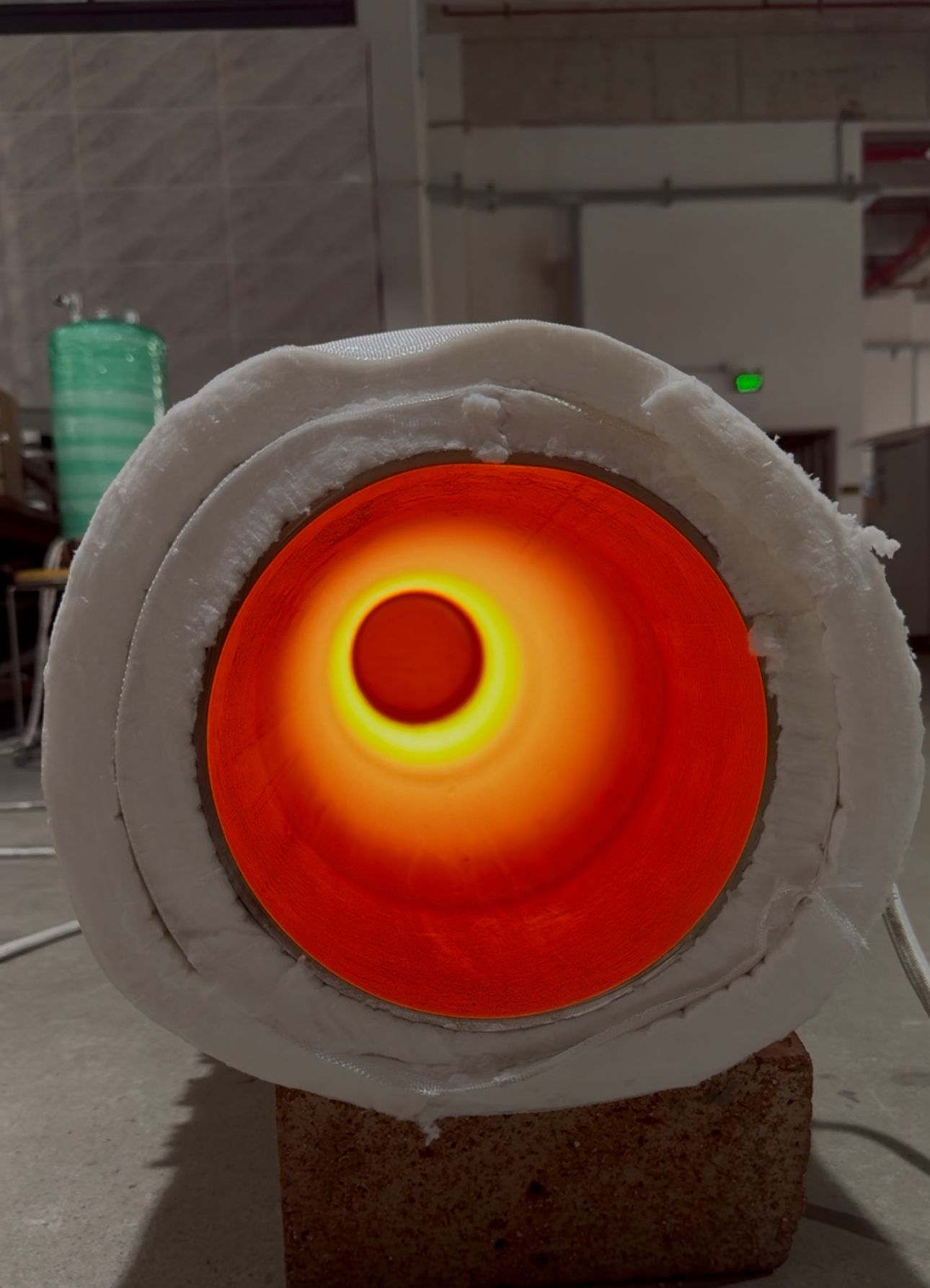

What is induction heating black technology?

Imagine using a microwave to heat metal!

The principle is to use 91勛圖厙 fields to generate heat through friction inside the metal:

1. Coil electrification generates a rotating magnetic field

2. Magnetic field excites eddy currents in 310S

3. Eddy current generates heat when it encounters resistance (like quickly rubbing hands to generate heat)

Why is induction heating necessary?

1. Hurry up!

310S itself has good conductivity and heats up instantly, saving time and electricity

2. Point to where to heat the parts that need to be treated (such as welding points), and let the other parts cool down

3. Non dirty hands, no need for flame contact, and can also be combined with inert gas to prevent oxidation

4. The computer controls the temperature of the precision repeater, and the heating effect is the same every time

5. Small deformation heat affected zone, and thin-walled parts are not afraid of warping into emoticons

Where is it actually used?

1. Manufacturing furnace components (such as radiation tubes, heat exchangers)

2. Preheat before welding pipes to prevent thermal expansion, contraction, and cracking

3. Annealing treatment - softening back the work hardened parts

4. Precision brazing (only heating the joint without damaging the overall structure)

5. High temperature equipment in the glass and ceramic industry (this product is locked with the high-temperature workshop)

matters needing attention:

1. When the surface heats up quickly at high frequencies, the heat is concentrated on the skin, and thick workpieces need to lower the frequency and gradually heat up

2. Magnetic mysticism: At room temperature, the cold processing area may have weak magnetism, but at high temperatures, it becomes completely "Buddhist like"

3. Keep a close eye on the thermometer. It is recommended to use an infrared thermometer to prevent it from overheating too much

Summary:

310S stainless steel+induction heating=the divine combination of high-temperature industry!

One is responsible for carrying and manufacturing, while the other delivers energy with precision.

Whether it's making rocket parts (exaggerated) or repairing furnaces, this CP can boost your production efficiency and save you time and effort.

With the advancement of technology, this pair of partners will definitely show off their skills in more bizarre high-temperature scenes!