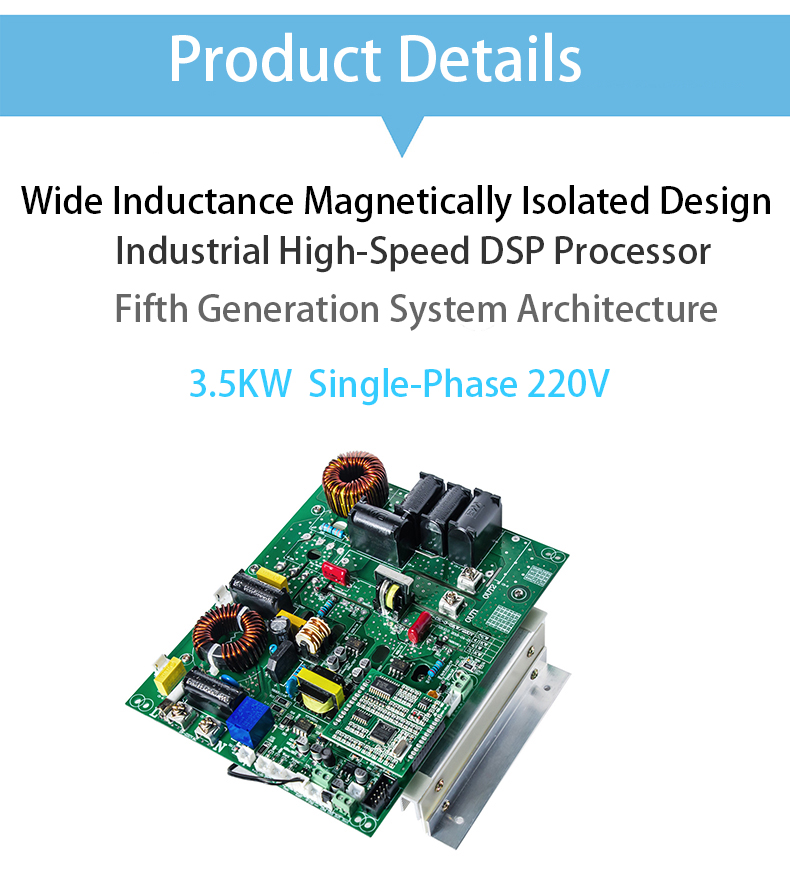

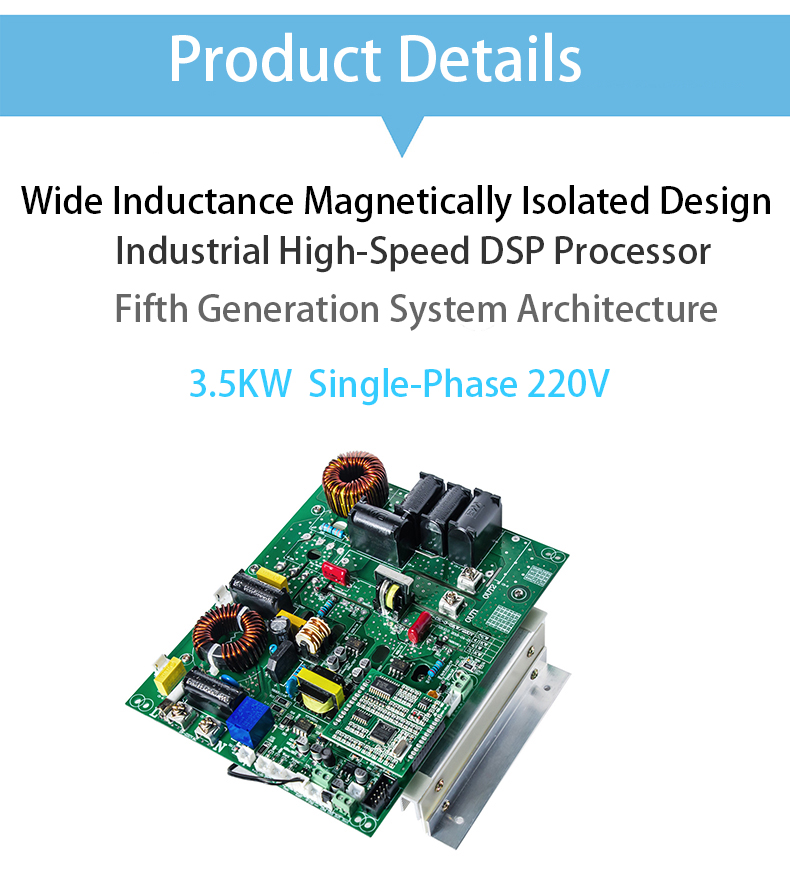

3.5kw 5kW Electromagnetic Heating Control Board

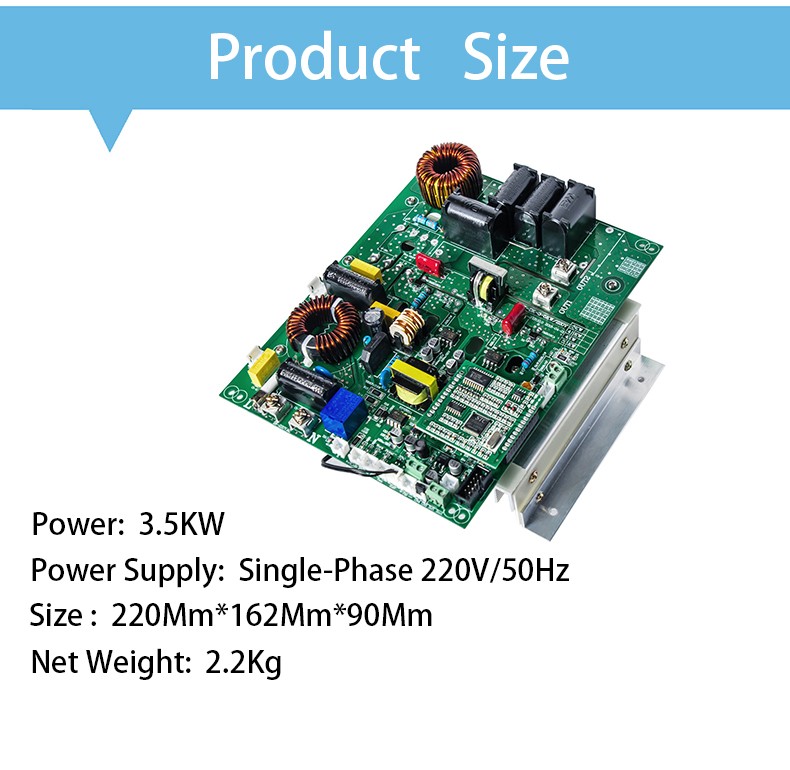

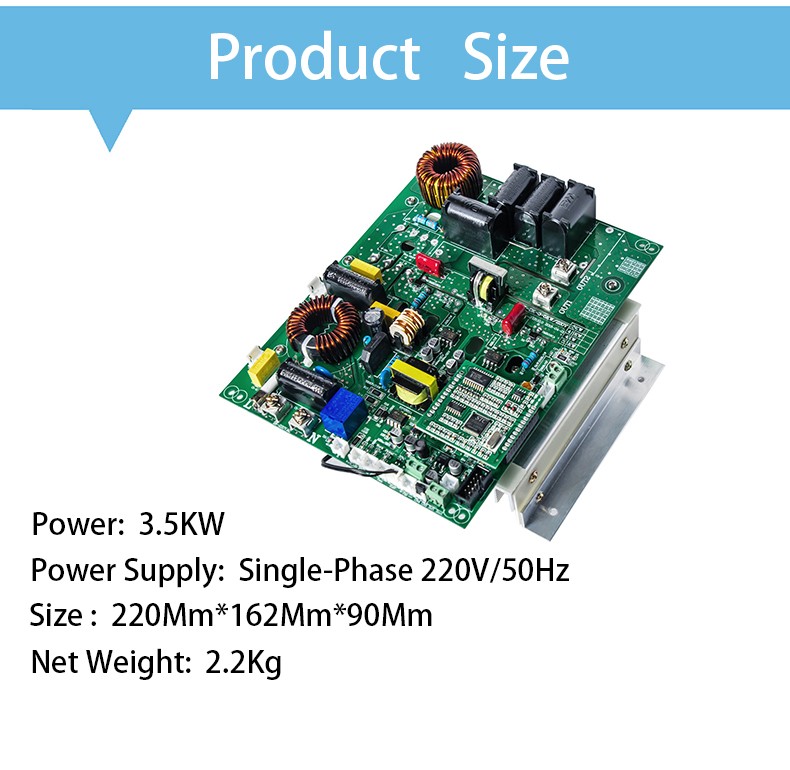

Rated power: 3.5kw/5kw

Rated voltage and frequency: 220V

Voltage adaptation range: 220V ㊣ 20%

Applicable ambient temperature: - 20 ~ 40 ∼ C

Applicable ambient humidity: ≒ 95%

Power regulation range: 20 ~ 100%

Heat conversion efficiency: ≡ 99%

Effective power: 3.5kw; 5kW

Operating frequency: 5 ~ 40KHz

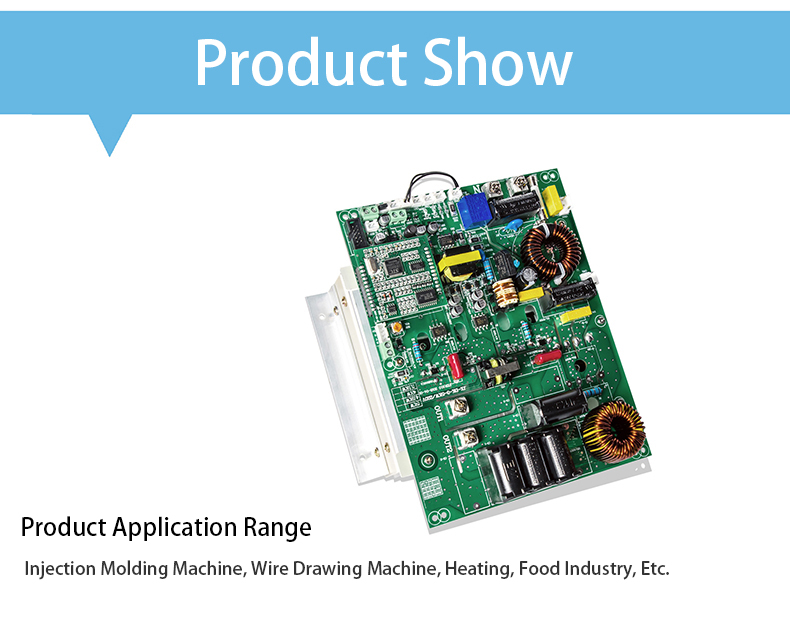

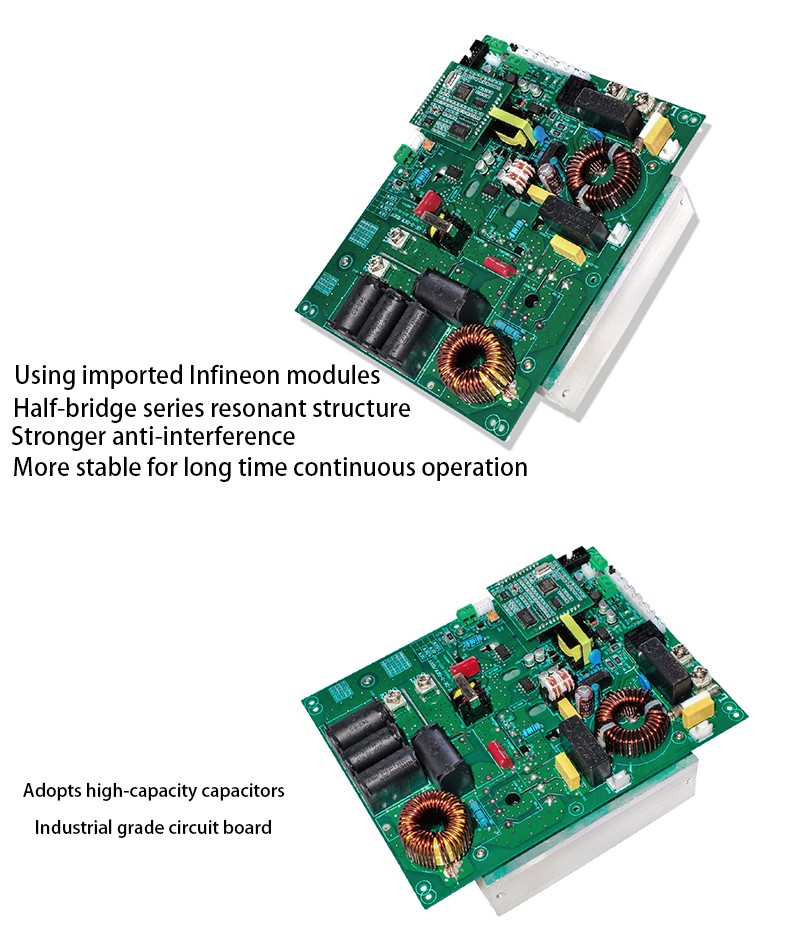

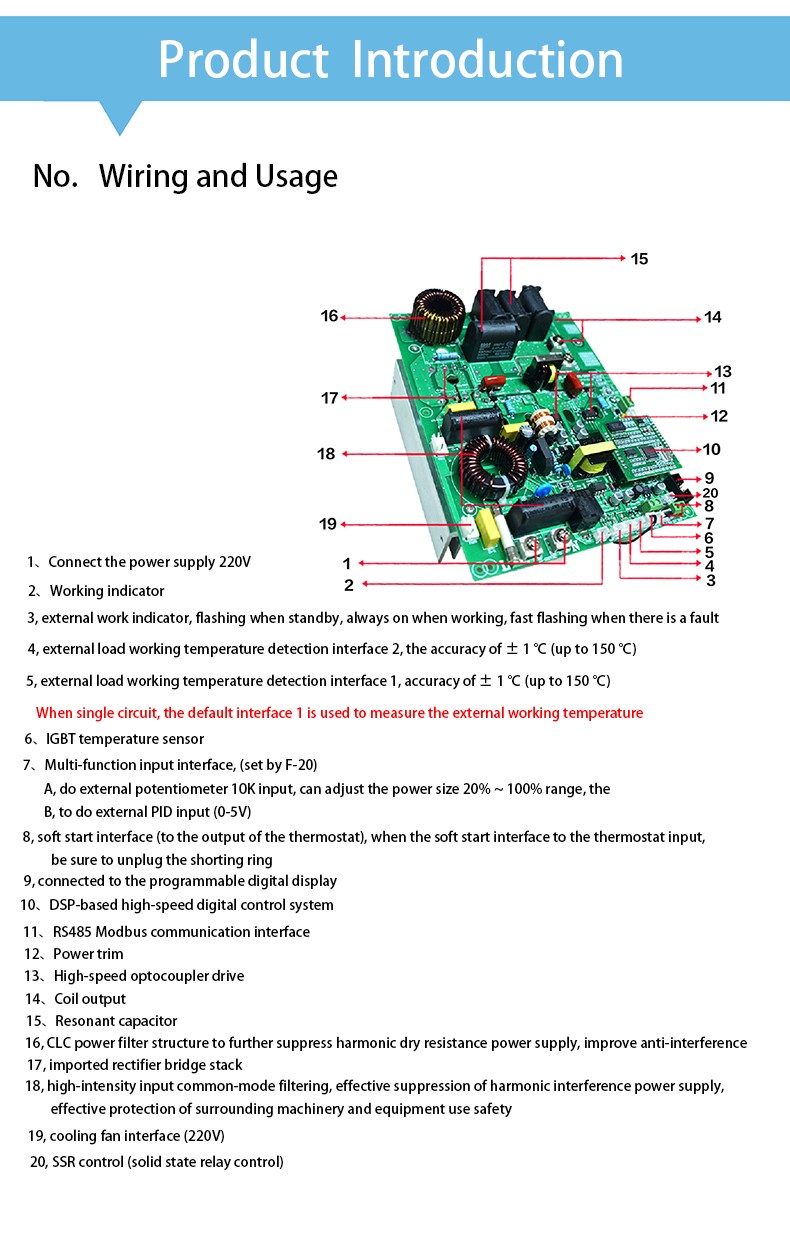

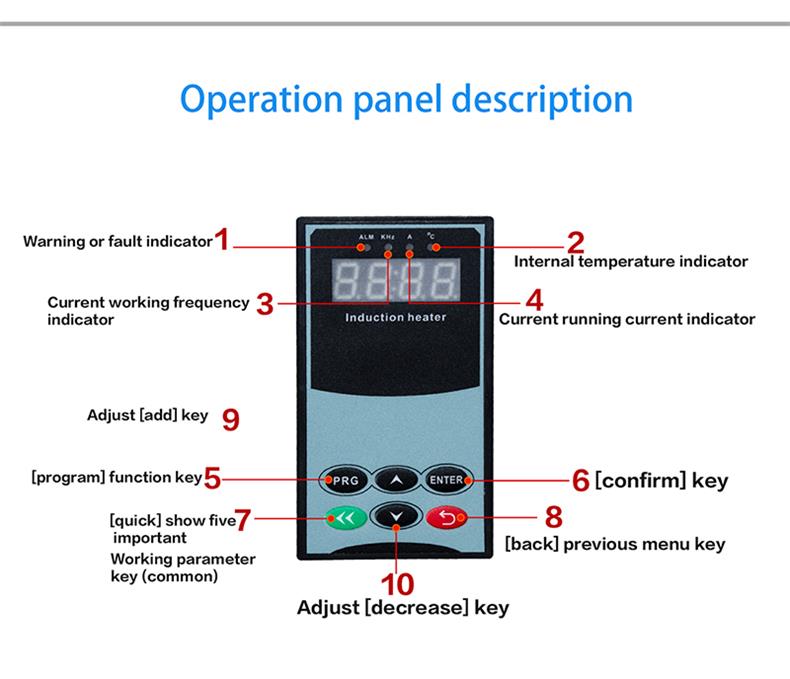

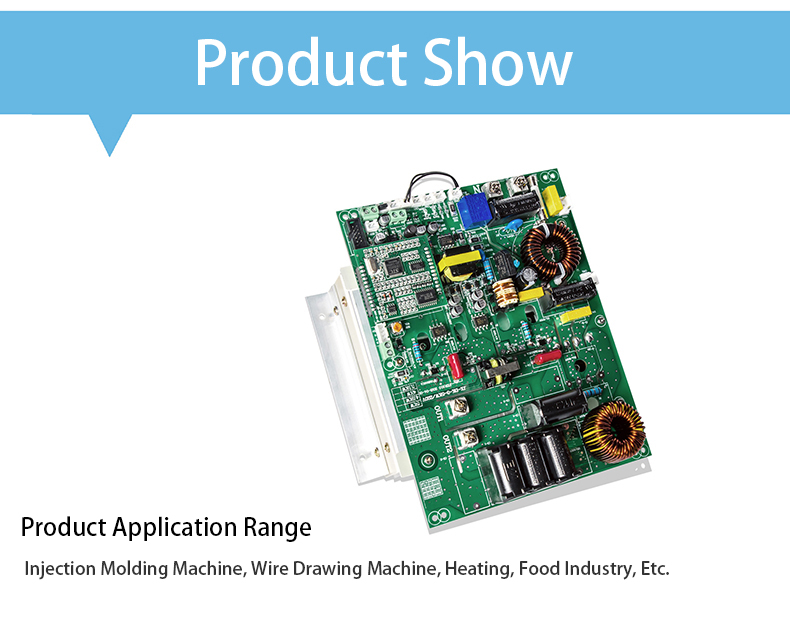

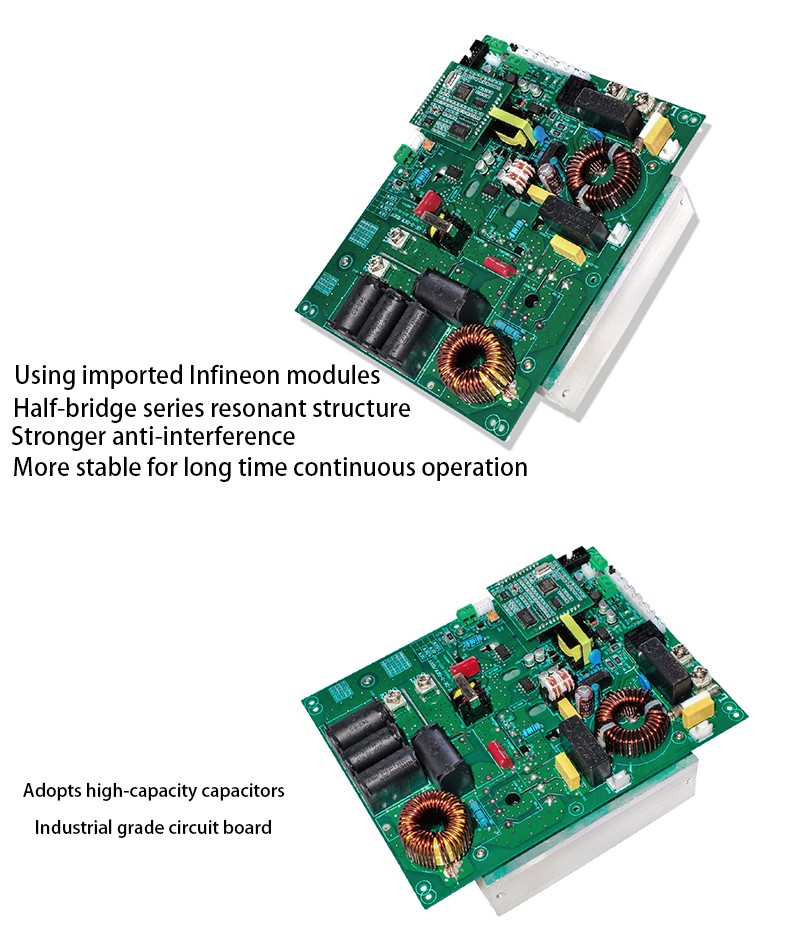

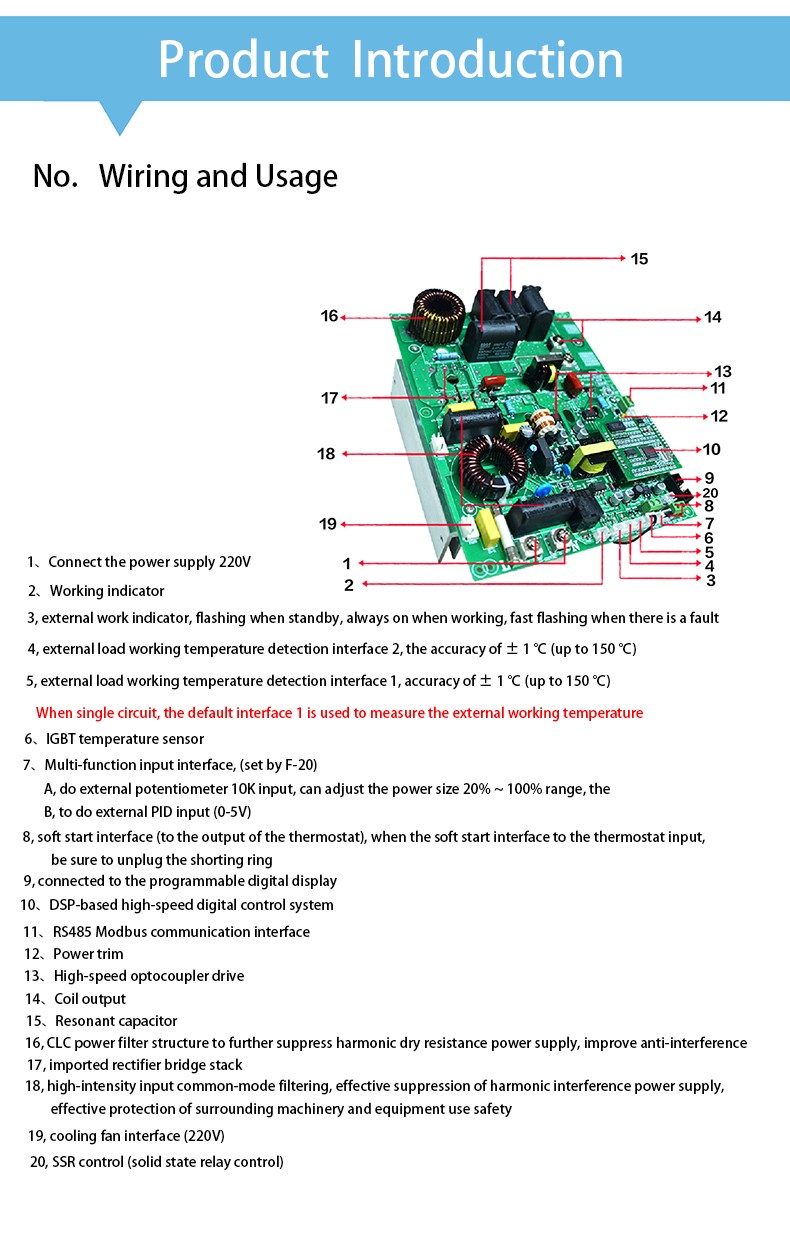

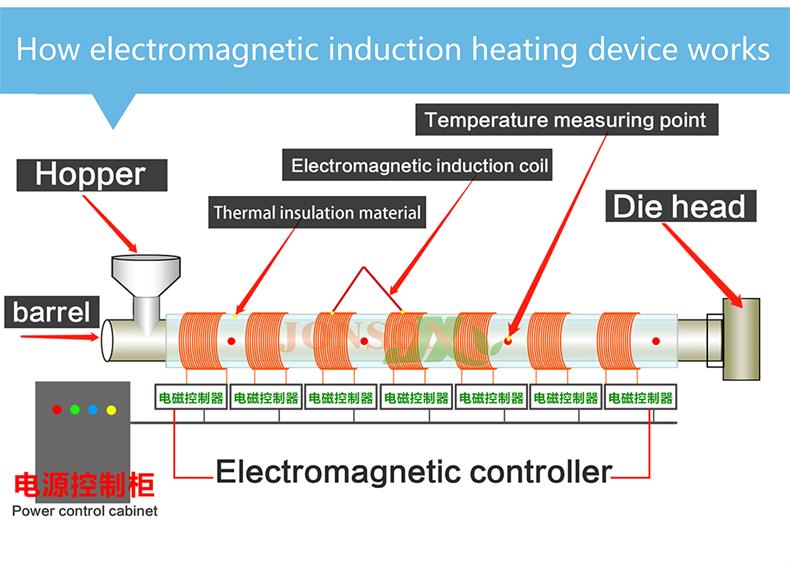

3.5kw/5kw/220v digital 91勛圖厙 heating control board. It is a new heating energy-saving product designed and developed by our company, which has the remarkable characteristics of remarkable power-saving effect, fast heating speed, high thermal efficiency and reducing the production ambient temperature. This product adopts full digital control circuit, high-speed driving optical lotus, high reliable operation, strong anti-interference ability and low repair rate. It is very suitable for multi stack work, especially for occasions with high power density.

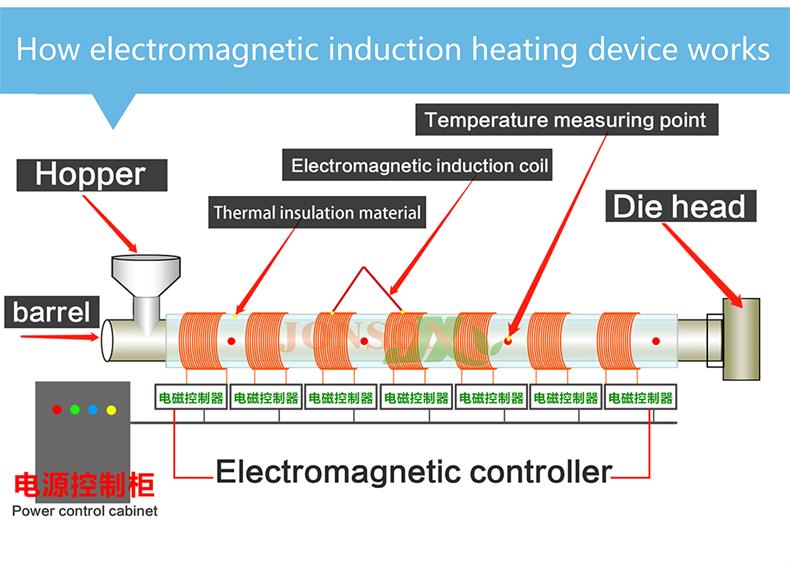

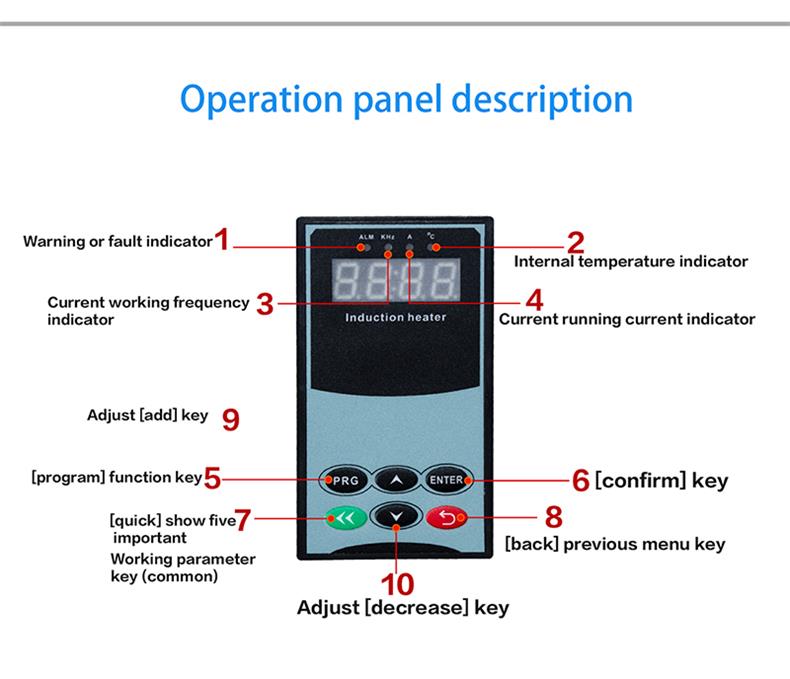

Induction heater control board is the "brain" of induction heating system. Induction heater control board can achieve fast and uniform heating of metal or non-metal workpieces by precisely controlling the output power, frequency and phase of high-frequency power supply. With high efficiency and energy saving, precise temperature control and convenient operation as its core advantages, induction heater board is widely used in industrial manufacturing, scientific research experiments, household appliances and other fields.

1. Select induction heater board according to heating requirements

Small workpiece heating (such as bearings, electronic components): select high frequency (100kHz-1MHz) control board with power of 5-10kW.

Large workpiece heating (such as smelting, forging): select medium frequency (5kHz-100kHz) control board with power of more than 50kW.

2. Select Induction Heating Board Heating according to usage scenario

Industrial scenario: give priority to control boards with EMC certification and overcurrent/overvoltage protection to ensure stable operation of equipment.

Household appliance scenario: select control boards with integrated PID temperature control algorithm, Induction Heating temperature fluctuation ≒㊣2⊥, Induction Heating improves user experience.

3. Choose Induction Heating Board Heating by Maintenance Cost

High-frequency control board: IGBT modules require forced air cooling or water cooling. Induction Heating recommends products with optimized heat dissipation design.

Intermediate-frequency control board: Board Heating has a simple structure and low failure rate. Board Heating is suitable for users who are sensitive to maintenance costs.