Induction heating power supplies are the core components of induction heating systems, responsible for generating the high-frequency electrical energy required to heat the workpiece through 91勛圖厙 induction. These power supplies are made up of several key components, each contributing to the functionality, performance, and efficiency of the system. Below is an overview of the main components of an induction heating power supply:

1. Power Input and Rectification Circuitㄩ

The first stage of an induction heating power supply is the conversion of the AC input (typically 50/60Hz from the electrical grid) into DC power. This is done through a rectification circuit that uses components like diodes or rectifiers. The rectifier converts the alternating current (AC) to direct current (DC), which is necessary for the subsequent high-frequency switching process.

2. Inverter Stageㄩ

Once the input power is rectified into DC, it is then fed into the inverter section. The inverter is responsible for converting the DC power into high-frequency AC power, typically between 1kHz and 100kHz, which is suitable for induction heating. This process is carried out using insulated-gate bipolar transistors (IGBTs) or metal-oxide-semiconductor field-effect transistors (MOSFETs), which act as switches to pulse the DC voltage at the required frequency.

3. Matching Networkㄩ

To ensure efficient power transfer from the inverter to the induction coil, the power supply typically includes a matching network. This network consists of a set of capacitors, inductors, and sometimes transformers to match the impedance between the inverter output and the induction coil. Proper matching ensures maximum power efficiency and minimizes losses.

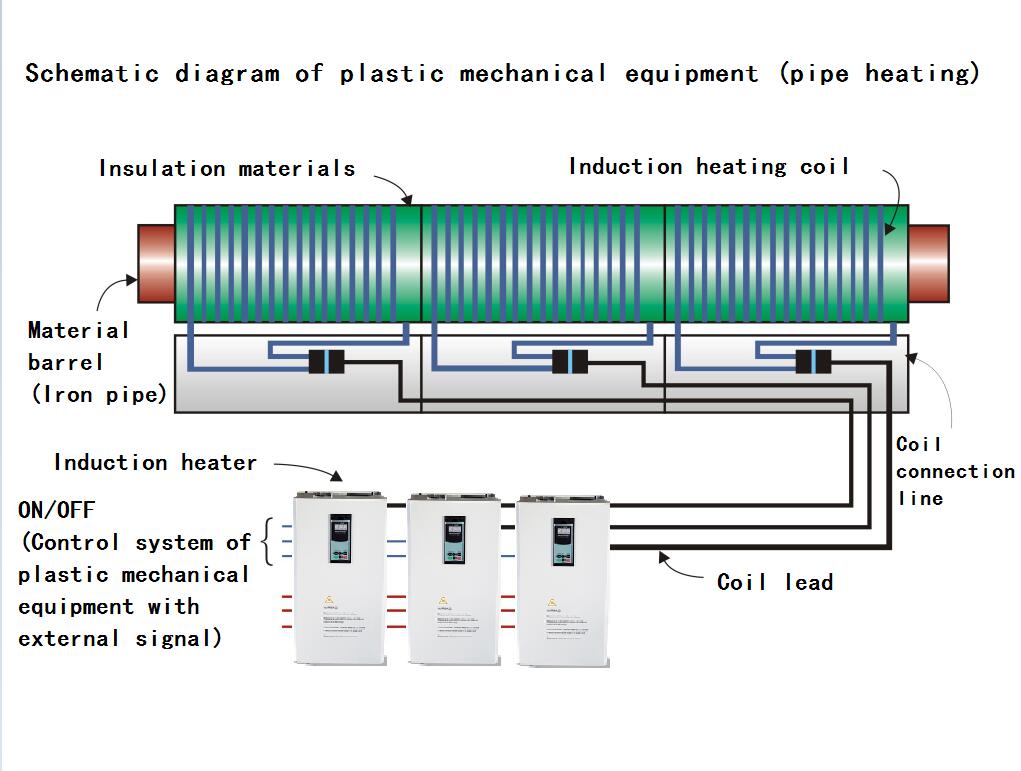

4. Induction Coilㄩ

The induction coil, often a copper coil, is placed near the workpiece and is energized by the high-frequency AC output from the inverter. This coil generates a rapidly changing magnetic field that induces eddy currents within the conductive material of the workpiece, causing it to heat up. The coil design, size, and number of turns are critical to achieving the desired heating effect.

5. Cooling Systemㄩ

Induction heating power supplies generate significant heat during operation, especially at high power levels. To prevent overheating of the components, a cooling system is essential. This can include air-cooling or water-cooling systems that are used to dissipate the heat generated by components like the inverter, capacitors, and coils. Water-cooled heat exchangers or fans are commonly used for efficient heat dissipation.

6. Control and Feedback Systemㄩ

The control system is the brain of the induction heating power supply. It manages the operation of the inverter, adjusts the power output, and ensures the system operates within safe parameters. Microcontrollers or digital signal processors (DSPs) are typically used to monitor and adjust the frequency, power, and temperature. The feedback system may include sensors like current sensors, voltage sensors, and temperature sensors to continuously monitor the system's performance.

7. Protection Circuitryㄩ

To protect the power supply and the workpiece, various protection circuits are employed. These include overcurrent protection, overvoltage protection, short-circuit protection, and thermal protection. The protection circuitry ensures that the system operates safely and prevents damage to the components due to electrical faults or overheating.

8. User Interfaceㄩ

The user interface allows the operator to interact with the induction heating system. This can include a digital display, touchscreen, or buttons for controlling settings such as frequency, power output, heating time, and temperature.

Conclusion

In summary, an induction heating power supply is composed of several key components:

1.Power input and rectification circuit to convert AC to DC.

2.Inverter to convert DC to high-frequency AC.

3.Matching network for efficient power transfer to the induction coil.

4.Induction coil to generate the magnetic field for heating the workpiece.

5.Cooling system to prevent overheating of components.

6.Control and feedback system for adjusting and monitoring operation.

7.Protection circuitry to safeguard against faults.

8.User interface for system control and settings.

Each of these elements works together to provide efficient and precise induction heating for a wide range of industrial applications.