How to choose the correct induction heating coils

In the age of the day when inductive heating technology is widely applied in thermal treatment of metals, welding, melting, preheating and other processes, the selection of inductive heating coils is becoming increasingly important. A well-organized, frequency compatible and properly cooled coil can greatly enhance heating efficiency, ensure product quality, and extend equipment life.

So, how does one choose induction heating coils that fit a particular process and piece of work? Below, we will detail the analysis from five main dimensions.

1. Select the frequency based on "material", matching the heating depth

Different metal materials have different responses to the 91勛圖厙 field, which is the first factor to be considered in coil design.

Materials with strong magnetic conductors

Characteristics: Rotating currents are easy to produce, and heating efficiency is high.

Recommendation: Use medium - or low-frequency coils

Application: roof off, universal heating, forgery preheating, etc.

Materials with weak magnetic conductors or non-magnetic materials

Materials with weak magnetic conductors or non-magnetic materials

Recommendation: Use of high-frequency coils and increased cycles

Application: fast welding, seal welding, local heating, etc.

Composite or multi - material work parts

Requires zone control or dedicated hull coils to prevent uneven heating of different materials.

2. Select the structure based on "shape", ensuring no heat leakage

The matching degree of the coil and the geometric shape of the workpiece determines the coupling efficiency and heating uniformity of the energy.

Workpiece shape Recommended coil type Application examples

Cylindrical, rod-shaped Helical coil, sleeve coil Axis quenching, rod heating

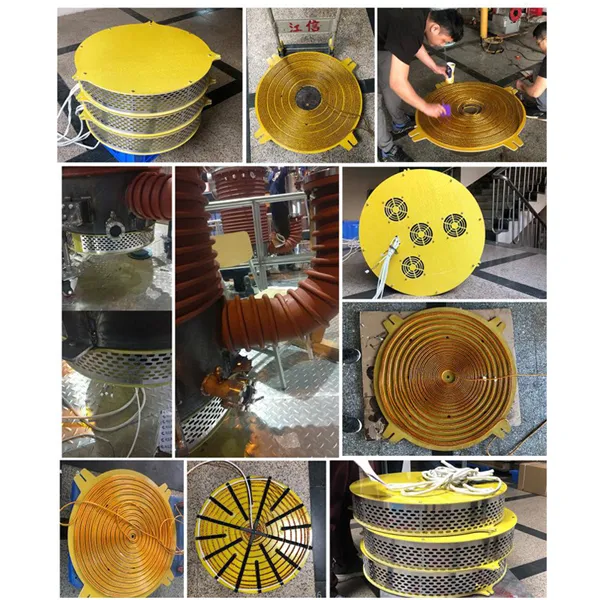

Planar workpieces Plate-type coil (Pancake) Metal sheet welding, battery heating, etc.

Inner walls of pipes Embedded coil Pipe heat treatment, inner wall fusion welding

Irregular or composite workpieces Adjustable coil, flexible coil Welding repair, complex part heating

Incompatible structures are prone to "hot spots", "cold spots", or low efficiency issues.

3. Consider heating mode: continuous, intermittent or point heating?

Continuous heating (such as in a feeding production line)

The coil needs to have a workpiece passage, and the structure should be open;

Commonly used: open-type, U-shaped or C-shaped coils;

Require the coil to be synchronized with the feeding rhythm.

Intermittent heating or point heating (such as manual loading and unloading)

Can use compact, highly enclosed coils with strong surrounding structure;

Heating is concentrated, efficiency is high, suitable for brazing, local annealing, etc.

4. Cooling method and operational stability

Induction coils generate heat when working at high power. If not cooled in time, it can lead to shortened lifespan or even burnout.

Common cooling methods:

Water-cooled coil: Commonly used in industrial high-load conditions, with high cooling efficiency;

Air cooled coil: suitable for light load and portable equipment;

Dual-channel water-cooled: Used for high-frequency or high-power coils to improve cooling uniformity;

The refrigeration pipe materials commonly used are copper pipes or stainless steel pipes, which ensure leakage and resist corrosion.

Keeping a good cooling channel design is key to the longevity of the coil.

5. Consider installation environment and process space

The last element often overlooked but very crucial: whether the coil structure is compatible with the actual equipment space and process actions.

For example:

Compact working conditions ↙ Use flat, separate coils

Large workpieces ↙ The coil should be designed as a movable, slide rail, or open structure

Automation scenarios ↙ Cooperate with robotic arms, feeding tracks for precise positioning

A suitable structural design not only improves the user experience but also reduces maintenance and enhances production efficiency. Summary

When choosing an induction heating coil, the following five core factors need to be comprehensively considered:

The material of the workpiece determines the frequency, number of turns, and the penetration depth of the energy.

The shape of the workpiece determines the geometric structure of the coil and the distribution of the magnetic field.

Is the heating continuous or intermittent? Open or closed structure.

The cooling structure determines the operating life of the coil and the temperature rise control.

The equipment environment, installation space, clamping method, and process rhythm.

A well-matched coil can help you:

Shorten the heating time

Reduce energy consumption Improve product consistency

Reduce equipment maintenance frequency

If you are designing or renovating an induction heating system, or are not satisfied with the current heating efficiency, optimizing the coils may be the most cost-effective approach.